Why is mesh lined outside for temporary strainer in gas application?

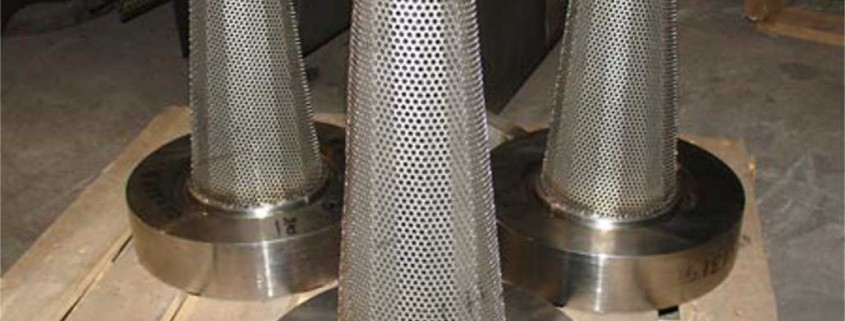

Any piping engineer will tell you that for a temporary strainer fitted in a gas application, the mesh needs to be lined on the outer side of the perforation and the flow of the gas must be from out to in (not the usual in to out). Have you ever wondered why the flow must be from out to in and the mesh on the outer side of the perforation? It is all got to do with cleaning of the temporary strainer during maintenance.

We all know that in a screen with mesh and perforation, filtration happens at the mesh. The perforation is only there to provide mechanical support to the woven mesh. As a thumb rule, the first point of contact for the fluid must be the mesh. In a gas application, the mesh is lined on the outer side of the perforation and the cone is positioned such that the flow hits the pointed side and flows from out to in. As a result all the unwanted particles, will get settled on the outer side of the cone. During maintenance, the temporary strainer is removed from the pipeline and using an air gun, a blast of air sprayed from in to out. As a result, all the unwanted particles that were trapped on the outer side of the cone are blown away. Now let’s assume that the mesh is lined on the inside and the flow is from in to out. In this case if the air gun is used to blow the air, the unwanted particles will keep getting stuck within the strainer and will not have anywhere to go.

Thus, in order for effective cleaning during maintenance, in a gas pipeline, a temporary strainer must have the mesh on the outer side of the perforation and the flow of the gas must be from out to in.