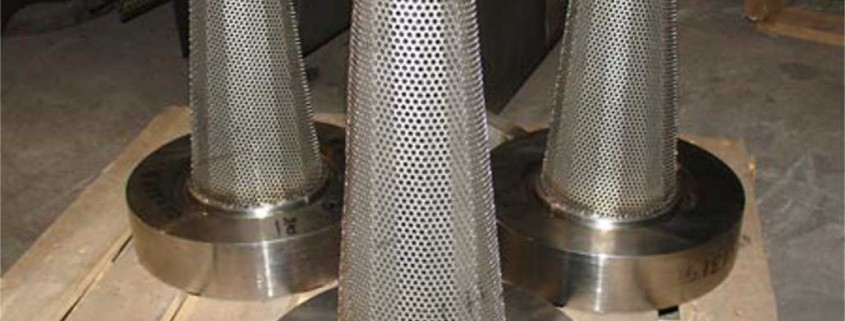

Flat-Bottom Basket Strainer for constrained layouts

Basket strainer is the preferred filtration option to handle high volumes of fluid or to provide large filtration area. Typically, a fabricated basket strainer’s body is constructed using a pipe and a dish (bottom cap). Depending on the diameter of the pipe, the cap constitutes to 25-30% of the total length of the lower body. The lower body is from the center flange to the bottom of the dish cap. In layouts where space is an issue, we can use the same sized basket strainer however the dish is replaced with a plate during fabrication. Such basket strainers are called a Flat-Bottom basket strainer.

They take 20% less vertical space when compared to regular dish bottom basket strainers. The drain, which is usually located at the bottom of the dish in a regular basket strainer, is located at the side for a Flat-Bottom basket strainer. This drain location further reduces the vertical space required to install a Flat-Bottom basket strainer. Pressure drop in a Flat-Bottom basket strainer is the same as a dish bottom type. The filtration area (open area percentage) is also not affected.

So if you are having vertical space issues in your layout and prefer only a basket strainer, try our fully customized Flat-Bottom basket strainer